Have you heard of Stihl connected yet? This smart new technology is designed to make your life easier by managing your tools for you.

Stihl connected is made up of 3 components:

- The Stihl Smart Connector (which is fitted to the tool)

- The Stihl Connected App

- The Pro Portal (online dashboard).

Stihl Connected is still really useful even if you aren’t a professional user as you can keep track of when your tools need servicing.

The Stihl Smart Connector and Stihl connected app are all you would need to use, whereas the Stihl Connected portal is designed specifically for professional fleet managers to make managing your tools simple and intuitive.

The Stihl Smart Connector is a Bluetooth hour meter. When fitted onto a cordless or petrol machine and paired through your Stihl Connected App, it counts the machine’s working time and sends it back to the smartphone app via bluetooth.

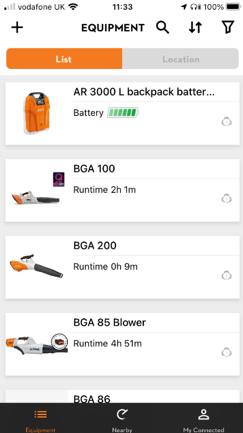

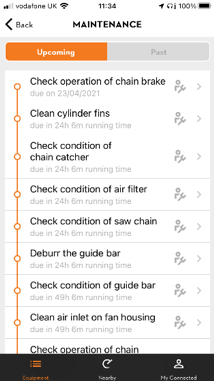

The Stihl Connected App looks like this:

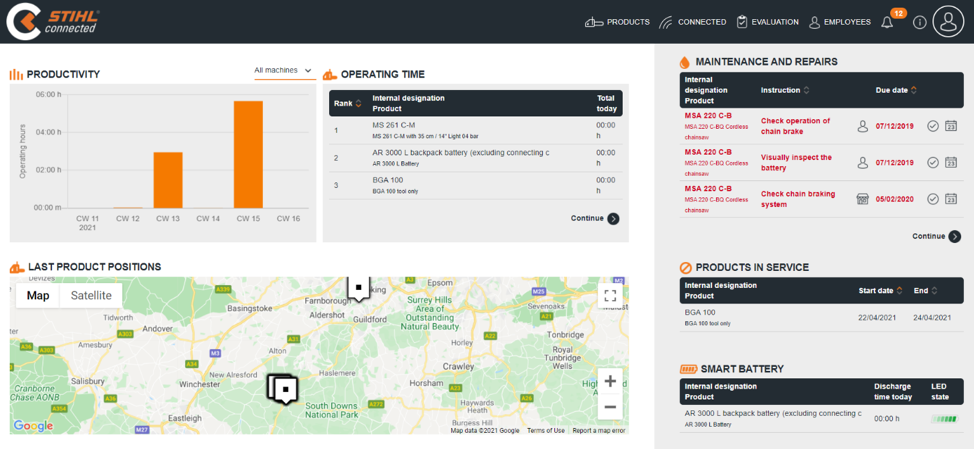

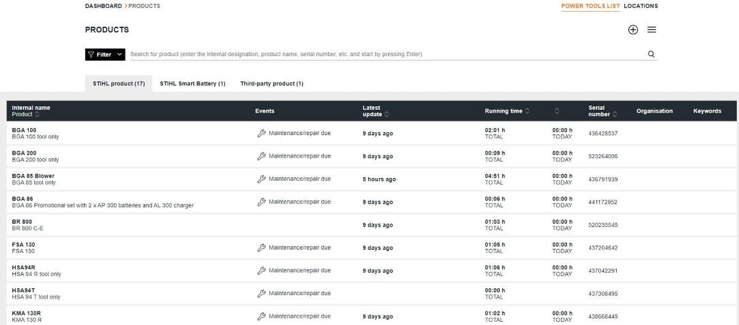

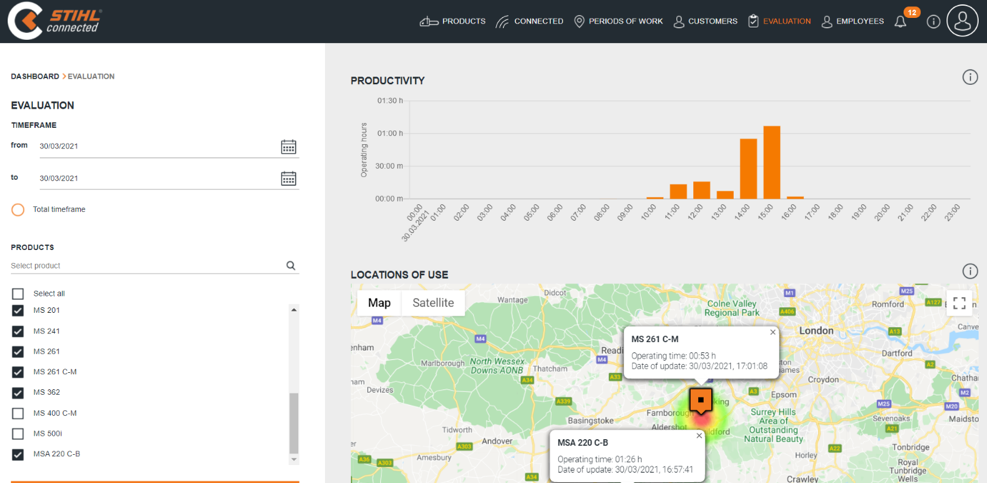

The Stihl Connected Portal looks like this:

If the Stihl Connected App isn’t open or within Bluetooth range (10m), then the Smart Connector will just continue to count the machine’s run time until the next time the app is opened near it.

The more regularly you open the app within 10m of the machine, the more accurate a picture of the machine’s usage can be built up; it's recommended that you open it daily, typically in the workshop at the end of the day would work well.

Although we’d love every machine to be a Stihl one, you can even use the Smart Connector with other brands or machine types.

You just need to stick the connector in a safe place on the machine where it can pick up an electrical signal from the machine when it’s running, such as on the casing near the spark plug or ignition unit. We’ve even heard of customers using the Stihl Smart Connector on their motorbike to remind them when an oil change is due!

What Use Is STIHL Connected To My Business?

You can see the status of all tools easily via the Stihl App and the Stihl Connected Pro Portal. If a machine’s in for a service, then with a quick glance of the app you know that it’s not available for a job.

Keeping on top of many different machines and user manuals can be difficult and tiresome – this puts all your maintenance in one place and can be accessed on the app or the desktop portal. For non– Stihl tools, you can add the maintenance schedules in yourself and it will remind you when the service is due. You can see this easily in the Stihl connected Portal and the STIHL Connected App.

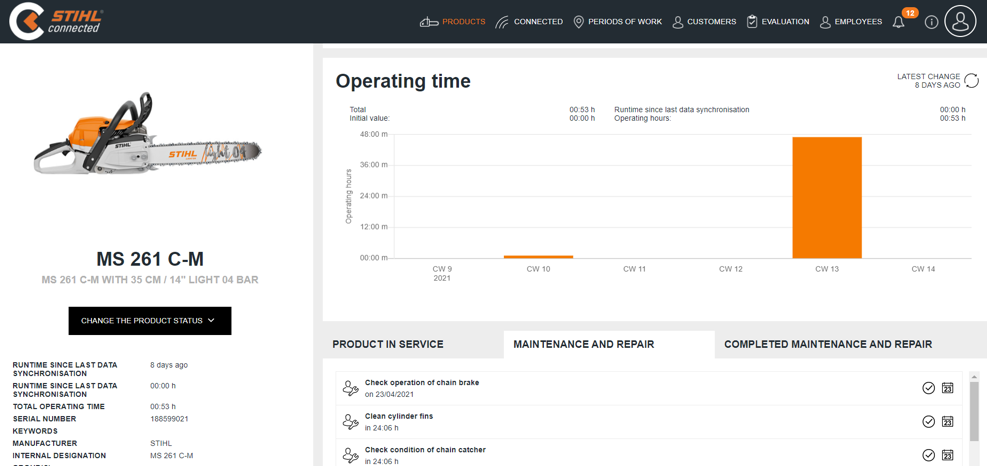

Stihl connected can give you insights into your tool fleet too. Instead of knowing how many times a tool has been out of the workshop, you get information about exactly how long it was used for. That allows you to service machines after a certain number of hours, rather than just guessing. Not only will the machine thank you for it, but you won’t be over-servicing a machine that may not need it – potentially saving the business time and money.

You can make sure tools are rotated too so they get even usage, rather than a good tool being left at the back of the workshop. It’s also useful to keep a record of the servicing of any tools for the purposes of PUWER (Provision and Use of Work Equipment Regulations 1998) – Stihl connected does exactly that!

It relies on a connection to a smartphone, so if a tool was left at a customer’s garden whilst connected to the Stihl app, it will show where the tool was last paired with the app. Or you can use it to check all the tools are nearby in the workshop after a day’s work. There’s no personal info or GPS data gathered by the Stihl Smart Connector – the only location that’s recorded is where you were whenever you opened the app. So if you only open the app and offload the runtime at the end of the day back at the depot, that’s the only location that will be shown, not where the machine was used that day.

Remember, the Smart Connector is just a Bluetooth hour meter – all of the clever functionality and location info comes from using the STIHL Connected app!

If you’re looking to purchase or replace tools – you can see which tools are the most used, under-used or not used at all, or which are best looked after based on their hours of use. That information can give you a much better insight to help choose the right new machinery for your business, and manage the life-cycle of your tools much better.